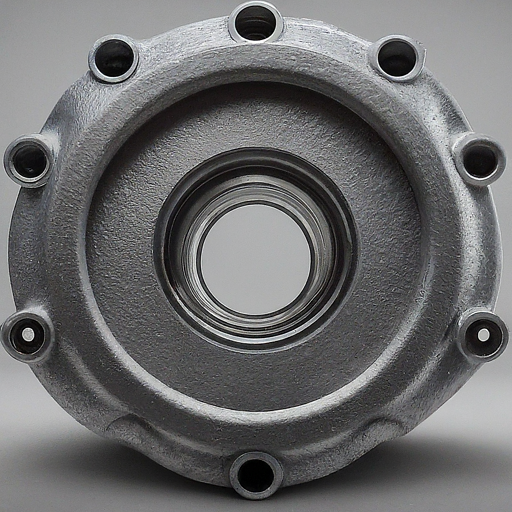

Zinc Phospahting

Each of the following features enhances value proposition.

Enhanced Oil and Wax Retention

Zinc phosphate creates a microscopic surface topography that attracts and holds onto rust-preventive oils and waxes, providing a long-lasting protective barrier against corrosion.

Superior Corrosion Protection

The combined effect of the oil/wax layer and the phosphate coating itself offers excellent corrosion resistance, extending the lifespan of treated metal components.

Diverse Applications

This combination of benefits makes zinc phosphate a popular choice for various applications, including automotive parts, construction materials, fasteners, and appliances.

Cost-Effectiveness

Compared to other corrosion protection methods like hot-dip galvanizing or anodizing, zinc phosphate is generally a more affordable option. This makes it a suitable choice for various applications where cost is a crucial factor.

Our Products

It offers several advantages in industrial processes compared to traditional phosphating methods conducted at higher temperatures.

UNIKOAT 450

Efficient and Targeted Protection:

Steel and iron get a slippery boost! This zinc phosphate dip, applied within minutes, helps them hold onto lubricants better. Less friction means smoother drawing, less wear, and a faster process

Improved Drawing Performance:

The zinc phosphate coating creates a microscopic texture that helps hold onto lubricants better.This reduces friction between the metal and drawing dies, leading to smoother and more efficient drawing with less damage to the metal.

Temperature Control

The process operates within a specific temperature range (160°F - 190°F). This ensures optimal coating formation and avoids undesirable effects like excessive heat damage to the metal.

UNIKOAT 600

Unmatched Deformation Resistance:

Developed specifically for deep draws and harsh forming, this zinc phosphate coating outperforms others with its unique composition. Imagine pushing metal to its limits without worrying about coating failure.

Superior Lubricant Retention:

The optimized phosphate-to-nitrate ratio and added metal accelerator create a tighter, more uniform coating that grips lubricants exceptionally well. Say goodbye to friction and wear during demanding processes.

Versatility across Applications:

Whether you use immersion tanks or continuous strand lines, this coating works reliably. It effectively holds onto different lubricants like borax, lime, or reactive options, adapting to your specific needs.