Why Low temperature?

Each of the following features enhances value proposition.

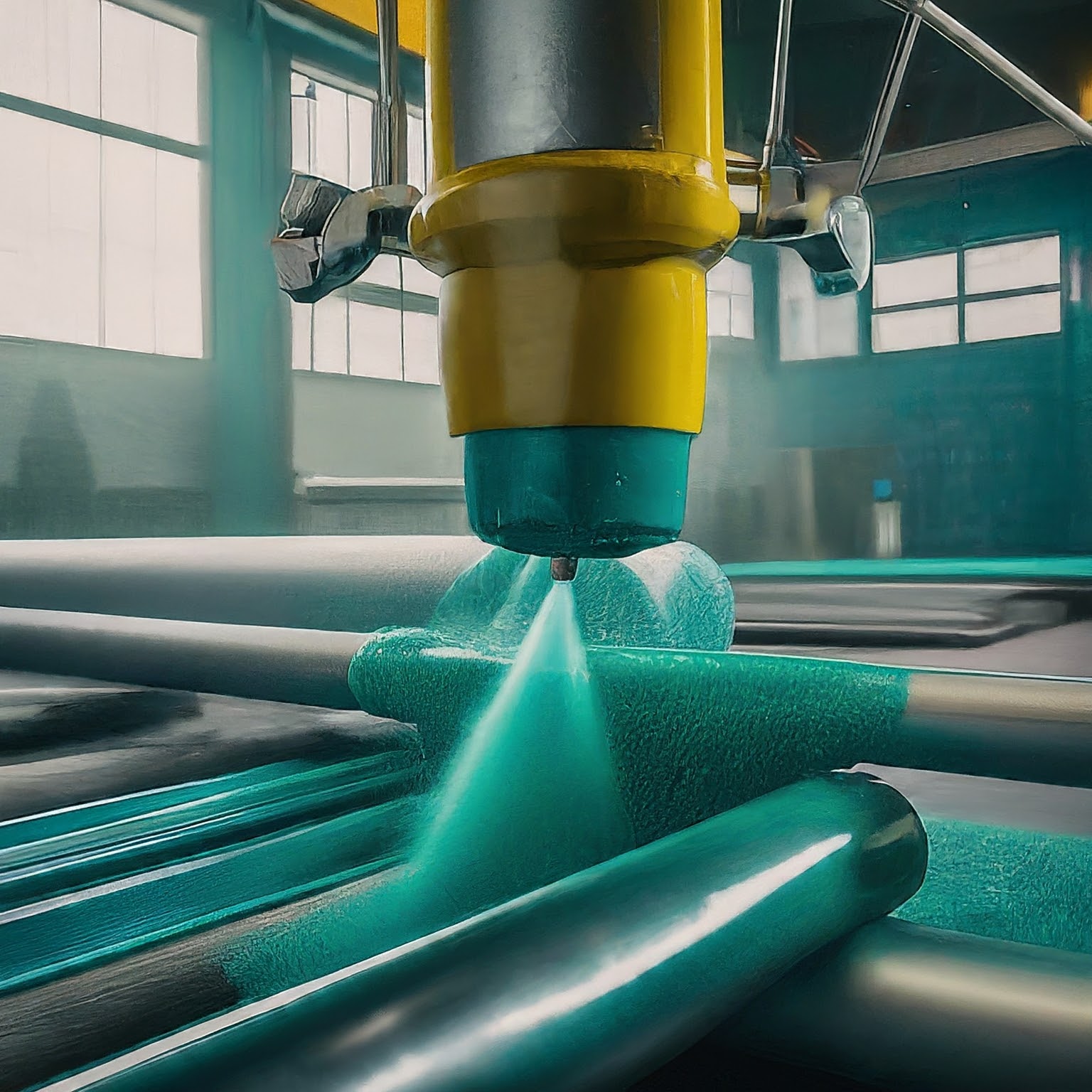

Enhanced Adhesion

Iron phosphate forms an amorphous, textured layer on metal surfaces, significantly increasing surface area compared to untreated metal. This "microscopic jungle gym" provides superior grip for paint and powder coat, ensuring a strong, long-lasting bond that minimizes the risk of peeling or chipping.

Improved Corrosion Resistance

The textured layer created by iron phosphate acts as a physical barrier, shielding the underlying metal from moisture and corrosive elements. This additional protection extends the lifespan of the coated object, reducing maintenance needs and enhancing overall durability.

Chemical Compatibility

Iron phosphates promote a strong chemical bond between the metal and the coating by removing surface impurities and creating a compatible layer. This eliminates adhesion issues caused by oil residues or contaminants, leading to a more uniform and aesthetically pleasing finish.

Environmentally Friendly

ompared to traditional chromate conversion coatings, iron phosphate is a much safer and more environmentally friendly option. It contains no heavy metals or harmful chemicals, making it a responsible choice for both workers and the environment.

Our Products

It offers several advantages in industrial processes compared to traditional phosphating methods conducted at higher temperatures.

UNIKOAT IP

Multi-functionality:

This product acts as a heavy-duty cleaner removing grime and impurities while simultaneously applying an iron phosphate coating on steel, zinc, galvanized, and aluminum surfaces. This eliminates the need for separate cleaning and pre-treatment steps, saving time and resources.

Enhanced Performance

The iron phosphate coating significantly increases the adhesion of paint and powder coat, while also offering improved corrosion resistance. This ensures a more durable and long-lasting finish for the treated metal.

Efficient Application

The product is specifically designed for use in spray washing machines at high temperatures (90°F-100°F) and a concentration of 25G/L. This allows for efficient and consistent application of the cleaner and coating in high-volume production settings.

UNIKLEAN IP3

Multi-metal compatibility:

Cleans and phosphates steel, zinc, and aluminum, making it versatile for various applications.

Simplified process:

Can be used in either three or five-stage spray operations, offering flexibility and potentially reducing steps compared to traditional methods.

Excellent pH stability:

Functions effectively in high pH environments, simplifying handling and potentially reducing maintenance needs.